We have compiled a list of LED fun facts that are informative and helpful to know.

For all those business owners, retailers, and houses of worship that have not yet committed to LED upgrades, these facts are important to consider.

- An incandescent lamp converts about 9-10 percent of the energy fed to it into light, whereas LEDs convert nearly 100 percent of the energy they consume as light.

- LEDs contain no mercury— and at least 95 percent of an LED is recyclable. Compare this to the wasteful design of compact fluorescent lamps (CFLs), which not only contain mercury, but also create a large portion of electronic waste due to their design — the fluorescent tube portion of a CFL ceases to work long before the ballast inside the CFL or its other electronic components are ready to die. This alone creates tons of waste every month.

- LED lamps on average are not subject to serious damage from external shock. If you drop an incandescent lamp, there will be a lot of broken glass to clean up, and if it’s a CFL, not only will it break, there are mercury decontamination procedures recommended by the Environmental Protection Agency you will have to follow.

- When LED light is used in fresh food displays, it has been proven to breed significantly less bacteria than its halogen or fluorescent counterparts.

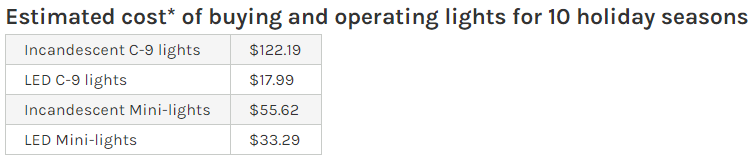

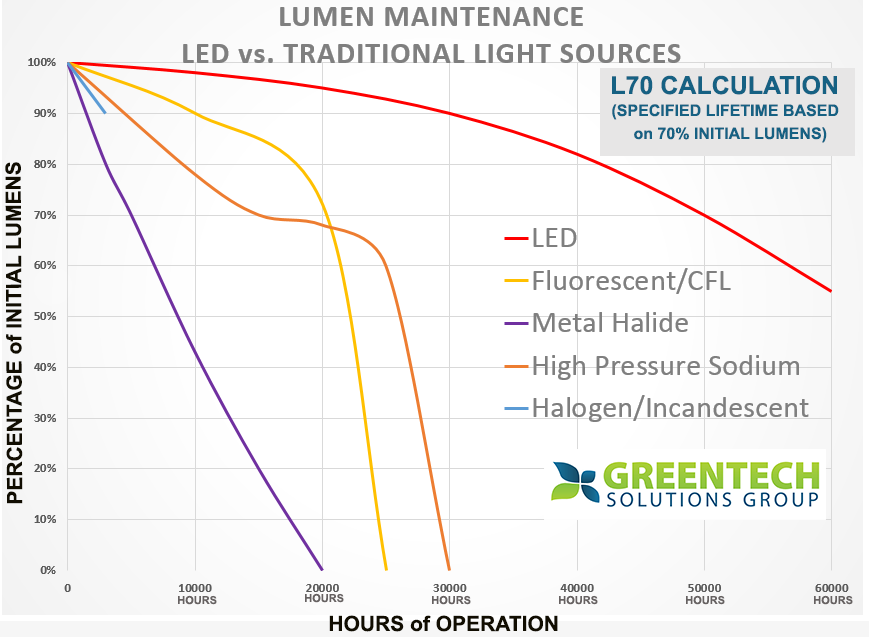

- A majority of residential/commercial LED A-lamp manufacturers claim a whopping 50,000 hours lamp life on average, with newer models claiming up to 100,000 hours. (Incandescent lamps have a lifespan of about 1,000 hours and CFLs have a lifespan of about 10,000 hours.) If this sounds impressive, it is! Consider your usage on just the 50,000 hour varieties:

- If you use your LED bulb for 24 hours a day, every day, that bulb is rated to last 6 years!

- If you use your LED bulb for 12 hours a day, every day, that bulb is rated to last 11 years!!

- If you use your LED bulb for only 4 hours per day, that bulb is rated to last 17 years!!!

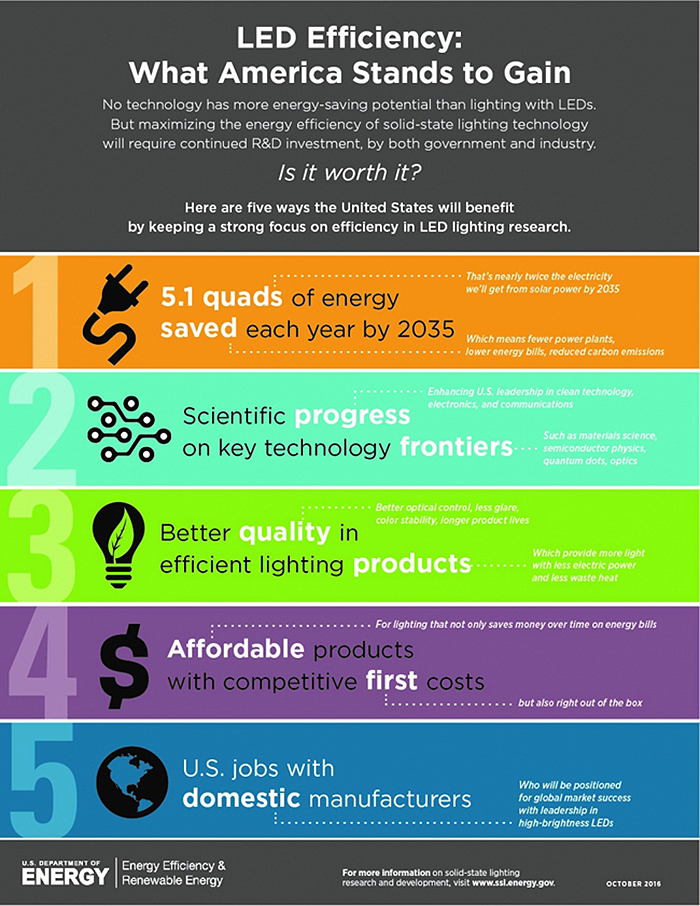

- The U.S. Department of Energy estimates that the widespread adoption of LEDs in residential and commercial applications over the next 20 years will save about $265 billion (Yes! That’s BILLION!), will prevent the need for constructing 40 new power plants, and reduce the electricity demand of lighting by 33 percent.

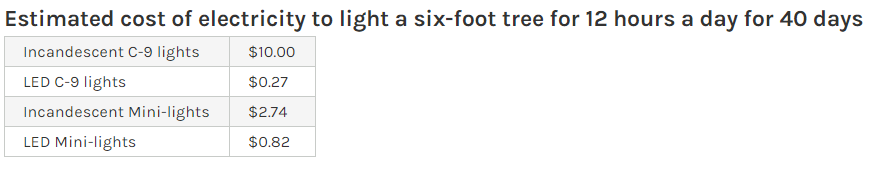

- If the entire United States would replace only 50 percent of the existing incandescent Christmas lights around the holidays, the potential energy cost savings starts around $17.2 billion dollars.

- Switch to an LED bulb in the porch light and you’ll notice considerably fewer bugs, if not a complete decrease in your porch bug population! Why? Because incandescent lamps and CFLs produce copious amounts of ultraviolet and infrared radiation, which attracts bugs.

- Due to the physics involved, LED lamps have what is called Instant On — unlike their incandescent and CFL counterparts. What this means is when you switch on an LED lamp, you get the full brightness of that light instantly. Incandescent lamps and CFLs experience significantly less lamp life from being switched on and off frequently, and CFLs in particular can experience greatly reduced lamp life if they are switched off and back on within 15 minutes of heating up.

- The lighting industries as a whole are pushing LEDs to replace incandescent sources in a variety of applications, but the first time that LEDs actually did displace incandescent lamps was in vehicle brake lights, signal lights, and traffic lights – back in 1987!

Contact us today to see how we can help you save money

Source: Kastor Energy March 2017

LINKEDIN

LINKEDIN