Ever wonder where your recycled plastic bottles end up? In Peninsula Packaging’s commitment towards sustainability, they are the largest consumer of recycled drink bottles for production of various food packaging products in the United States and have diverted over 42 million pounds of recycled plastic bottles from the landfill. Additionally, they own and operate the largest privately funded photovoltaic (solar) farm in North America. In efforts to further their sustainability goals, Peninsula Packaging were searching to find the best option for their lighting efficiency enhancements.

While aspiring towards an effective solution to increase the lighting quality, efficiency, and lumen output for their 110,000 sq.ft. manufacturing facility in Wilson, NC, they were struggling to find a partner who provided a reasonable value along with a turn-key solution. GreenTech Solution Group’s ability to provide a complete service from proof of concept to installation aligned with Peninsula’s desired need for a one-stop-shop solutions provider. GreenTech also offered a Waste Stream Report which validated the disposal and recycling destinations of the generated waste from the removal of older lighting fixtures. As a result, Peninsula Packaging experienced successful achievements due to the lighting retrofits:

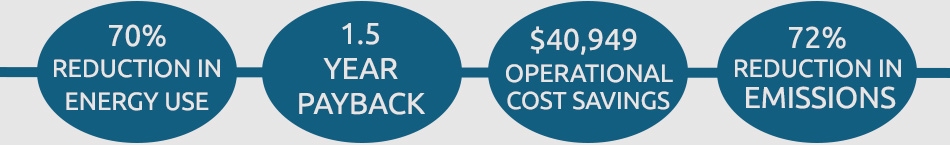

- 1.5 year payback period

- 70% reduction of energy and maintenance cost

- 52,320W in projected annual wattage savings

- $40,949 in annual operational cost savings

Along with these achievements, Peninsula Packaging also reduced their adverse impact on the surrounding environment often experienced with the use of old lighting technologies. By replacing all of their 400W metal halide magnetic fixtures with 185W LED linear highbay fixtures by Philips, they significantly reduced their company’s ecological footprint. With a 72% annual reduction of carbon dioxide (CO2) emissions, the release of 420.5 tons of CO2 has been avoided over a 10-year period. Their nitrous oxide and methane gas emissions have also been decreased by 72%, equivalent to 2.1 tons of CO2. These beneficial reductions of harmful emissions are comparable to the amount of carbon sequestered by 73 acres of trees being planted or 104 fewer cars on the road.

Peninsula Packaging exemplifies a model of responsible environmental stewardship and achieved a commendable milestone in their efforts towards sustainability. Greentech Solutions Group is proud to have been selected by Peninsula Packaging to provide resources to implement this project to further their goals to reduce their energy consumption and improve the lighting in their work areas.

LINKEDIN

LINKEDIN