Florida Marine Tanks LED Upgrade: 74% Reduction in Energy Consumption, 50% Cost Savings in Energy Rebates

The Challenge

Florida Marine Tanks is an ABA and IBBI preferred aluminum tank supplier committed to provide the marine industry with the safest and highest quality fuel, water and holding tanks and manufactures out of their Henderson, NC facility. The facility is fully equipped for sheet metal fabrication from high quality aluminum and stainless steel.

Florida Marine Tanks President Orestes Monterrey wanted to improve the lighting quality and efficiency of their 60,000-square foot facility in Henderson, NC. The goal was to make the work environment safer and more pleasant for employees, while reducing the company’s overall carbon footprint. Monterey also wanted to ensure that production was not affected during the factory-wide LED upgrade.

The Solution

GreenTech conducted a comprehensive lighting audit of Florida Marine Tanks’ existing system and provided an in-depth analysis, forecasting the energy and maintenance savings that result from an upgrade to energy-efficient LED lighting. It provided recommendations on converting T12 strip fixtures and out-dated metal halide highbays to LED solutions in order to maximize critical production lighting.

Lighting was also upgraded with dimmable LED panel lights throughout the offices, shops, workout area, and cafeteria that allowed for brighter and customized light levels as needed.

“It was a pleasure to work with the crew at Florida Marine Tanks. Seeing the impact the lighting upgrade made on their facility was very rewarding. You could not only literally see the difference it made to the environment, but you could also see how postively it affected the employees,” said GreenTech’s V.P. of Business Development Scott Jernigan. “We love projects that not only have a quick payback, but also improve the working environment.”

The Results

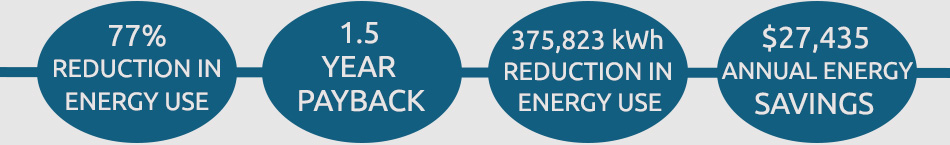

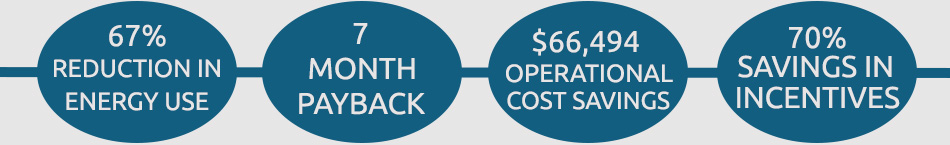

The complete LED lighting upgrade delivered a 74% reduction in annual lighting energy usage for Florida Marine Tanks for their manufacturing facility. Greentech helped the company secure 50% cost savings in energy rebates and incentives for the retrofit, bringing a quick 1.8 year payback period.

A summary of benefits includes the following:

- 74% reduction in annual lighting energy usage

- 1.8 year payback period

- 173,795 kWh reduction in annual lighting energy usage

- $17,379 in annual operating savings

- 50% cost savings in energy rebates and incentives

The LED upgrade resulted in dramatically better lighting quality that greatly helped to improve employee safety and increase productivity as well as producing a brighter atmosphere throughout the facility.

“From beginning to end GreenTech’s team was a pleasure to work with. Their crew was very efficient and professional. They were willing to work around our schedule to where our production didn’t get affected. The final product exceeded our expectations, and our employees are more productive and most importantly are able to work in a safer environment,” said Monterrey.

Monterrey added, “GreenTech’s ability to specify the needed upgrades in a precise fashion helped us gain a better idea of exactly what we were paying for. The rebate process was seamless as well with us receiving exactly what GreenTech quoted us receiving. We are very pleased with the outcome, and seeing a reduction in our utility bill made it that much better.”

LINKEDIN

LINKEDIN